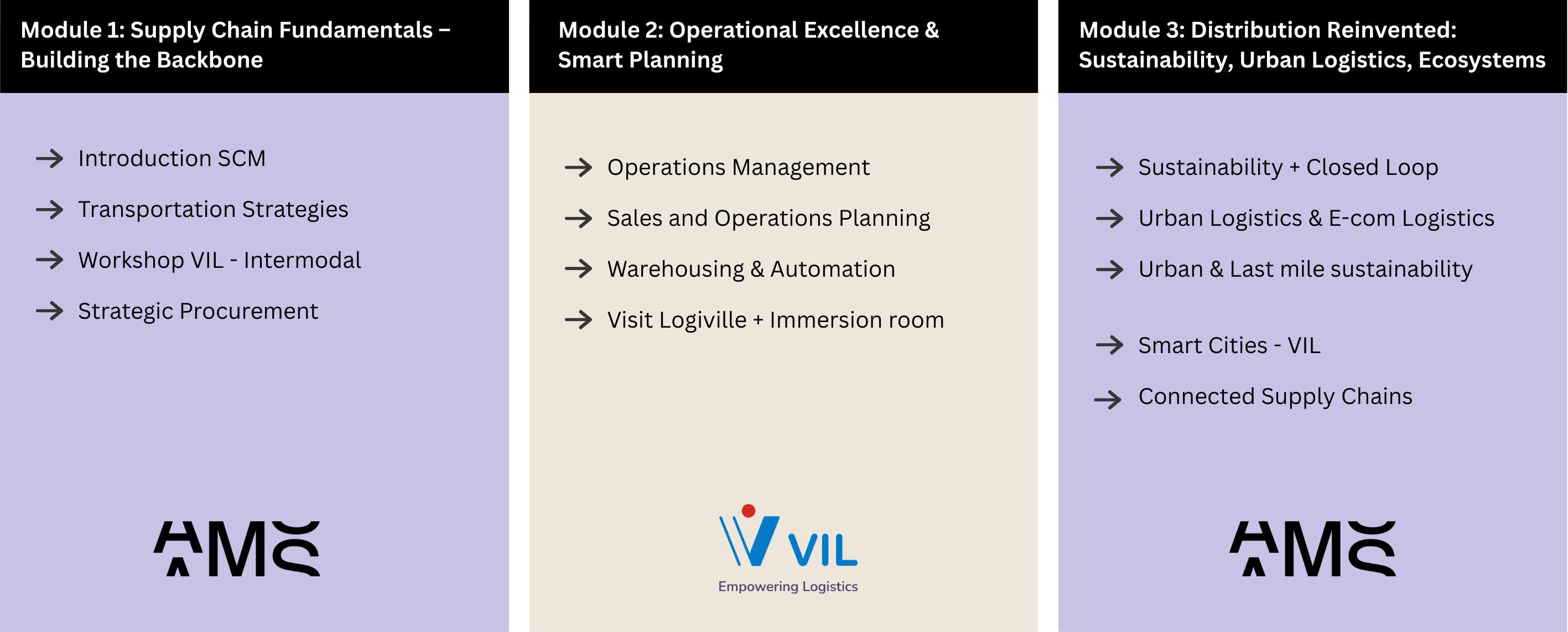

Modules

Module 1 and 3 are organized and hosted at AMS, while Module 2 is hosted at Logiville.

Module 1: Supply Chain Fundamentals – Building the Backbone

Introduction to Supply Chain Management – Prof. Roel Gevaers, PhD & Prof. Steffi Weil, PhD

Gain a powerful strategic perspective on how global supply chains drive economic value and risk. This session explores the rising boardroom importance of supply chain decisions in an era defined by geopolitical shifts, trade tensions, and systemic disruptions.

Transportation Strategies – Prof. Wouter Dewulf, PhD

Develop a sharp understanding of how to select and combine global transport modes—air, maritime, road, and rail—based on cost, speed, reliability, and capacity. This session focuses on strategic transport choices and management based on total cost analysis. How to deal with geopolitical tensions in transport will also be part of this session.

Hands-On Intermodal Logistics by VIL

Step into the complexity of real-world logistics. This interactive session immerses you in intermodal transport cases and planning, where you will tackle practical challenges in combining modes, optimizing flows, and meeting customer demands. A unique opportunity to apply strategy to action.

Strategic Procurement – Manu Matthyssens

Move beyond transactional sourcing and rethink procurement as a strategic driver. This session helps you to understand data-driven supplier strategies, improve negotiation performance, and align procurement with sustainability and long-term business goals.

Module 2: Operational Excellence & Smart Planning

Operations & Production Management - Prof. Christof Defryn, PhD

This session focuses on the core principles of managing production and operations within a supply chain context. Learn how to balance capacity, lead times, and inventory, and how tools like production planning, scheduling, and lean operations can help improve efficiency, reduce waste, and ensure reliable delivery. A practical guide to aligning daily operations with broader supply chain goals.

Sales & Operations Planning (S&OP) – Gilles Groetaers

Discover how to connect your supply, demand, and financial planning into one clear process. This session explains how S&OP and Integrated Business Planning (IBP) help teams work together, avoid surprises, and support better business decisions—supported by the right tools and systems.

Next-Gen Warehousing: Automation & Beyond – Prof. Roel Gevaers, PhD

Take a deep dive into the latest innovations in warehousing. Learn how to design smart warehouse networks, choose between centralized or decentralized setups, and apply automation to boost speed, accuracy, and flexibility. Discover how robotics, data-driven systems, and new fulfillment models are reshaping warehouse operations in the digital age.

Future Logistics in Action: Logiville Tour & Immersion Experience by VIL

Visit Belgium’s only supply chain innovation center and see the future of logistics in action. From warehouse robots to digital tools, this hands-on tour shows how new technologies are changing the way goods are stored, handled, and delivered

Module 3: Distribution Reinvented: Sustainability, Urban Logistics & Ecosystems

Building Sustainable & Circular Supply Chains – Ewald Van den Auwelant

Learn how to apply practical frameworks and models to design supply chains that are both efficient and circular. This session focuses on how to map material flows, implement closed-loop logistics, and measure impact using tools such as carbon accounting, circularity indicators, and lifecycle cost analysis. Gain actionable insights to balance environmental goals with economic performance.

The Urban Challenge: E-commerce & City Logistics Uncovered – Prof. Roel Gevaers, PhD

Urban areas are becoming the most complex and competitive zones for logistics. This session explores the real-world challenges of last-mile delivery, driven by booming e-commerce, road congestion, and access restrictions. Learn how companies are responding with innovative solutions such as microhubs, zero-emission delivery vehicles, cargo bikes, autonomous delivery, and emerging models like dark stores and dark kitchens. A strategic look at the future of urban logistics infrastructure.

Urban & last mile Sustainability methods Prof. Philippe Nimmegeers, PhD & Rafael Asciano

Learn how to make smart, data-driven choices in urban logistics. This session offers hands-on tools to calculate emissions, Total Cost of Ownership (TCO), and evaluate greener last-mile options. A practical approach to combining efficiency and sustainability in city delivery models.

Smart Cities: Urban Access Innovations by VIL

Explore how digital technologies—like blockchain and real-time access control—are reshaping freight flow in cities. This interactive session highlights public-private data sharing, urban access regulation, and how smarter coordination reduces congestion and boosts performance.

Connected Supply Chains: The Power of Data & Ecosystems – Prof. Roel Gevaers, PhD

See how digital leaders like Amazon and Alibaba run data-driven, connected supply chains. Understand how ecosystem thinking, real-time data, and AI are changing logistics—and how traditional companies can catch up by rethinking collaboration and visibility.